Whether customers are searching for furniture pieces for the bedroom, dining room, or living room, wood furniture remains a popular choice that offers tremendous value in any home. Wood furniture is a worthwhile investment that offers the natural beauty of wood with the resiliency and durability of the natural material. From traditional pieces to sleek and modern furniture, wood furniture knows no style boundaries and is easily incorporated into any lifestyle or aesthetic. The following guide distinguishes the most popular wood types, finishes, craftsmanship, and care, so that you are well-informed in purchasing the best, high-quality wood furniture for your home.

For the most part, hardwoods are generally considered denser (and thus, harder) than softwoods, although the terms do not technically determine its relative strength. Hardwood and softwood is distinguished botanically by the way it is produced, and is entirely dependent on the seed structure. A hardwood is produced by a seed with some sort of covering, be it in the form of a shell or fruit. A softwood is produced from an exposed seed left to the elements.

The most common way hardness is measured in woods is through the Janka Hardness Test, which measures the resistance of wood to denting and wear. An industry standard since 1906, the test measures the average amount of force required to “embed a .444-inch steel ball to half its diameter” in a piece of wood. Most ratings refer to a wood’s “side hardness”, which tests on the perpendicular side of the grain. The following measures the relative strength of different woods from softest to hard:

Different types of construction call for different kinds of wood types to be used. From structural to decorative functions, both hardwood and softwood can be used. The following outlines distinguishes the most common types of wood varieties used for furniture construction:

Pine is an inexpensive, lightweight softwood with a pale color. It is often used in unfinished furniture.

PROS: Best quality softwood, low-cost, resistant to warping, well-suited for painting/staining

CONS: Prone to scratches and dents

Cedar is a softwood with a light red color and a close grain. It has a distinctive scent which makes it effective in repelling insects.

PROS: Durable, resistant to insects due to natural oils

CONS: Not strong, cannot be bleached or stained, moderately expensive

A common hardwood often used in furniture, birch is similar in grain and color to maple with its light yellow brown color and close grain.

PROS: Strong, satin-like sheen, attractive coloration

CONS: Not weather resistant, coarser than maple, darker stains do not absorb well and blotching can occur

Often used with more expensive woods, beech is a light colored hardwood that bends easily, and is often used in the sides and backs of cabinets, drawer bottoms, and chair and table legs. It has a fine, tight grain.

PROS: Hard, heavy, high shock resistance, well-suited for polishing, inexpensive

CONS: Prone to warping, not durable to moisture changes

Ash is a tough hardwood well known for its bending abilities. It is extremely flexible without losing its strength, and is used for curved furniture. It is pale in color with a straight grain, and is a good alternative to oak.

PROS: Extremely flexible, strong, inexpensive

CONS: Staining can exaggerate the grain

Oak is a grainy hardwood that can range in color from grey-brown to red-brown. Red oak is usually less expensive than white oak.

PROS: Strong, durable, resistant to warping, distinctive look

CONS: Staining can exaggerate grain brining a two-tone finish

Pale in color with a reddish cast, maple is an attractive hardwood that is one of the hardest wood species.

PROS: Ultra durable, moisture resistant, stains well, affordable, ideal for furniture

CONS: Can look blotchy when not sealed properly

Typically chocolate brown in color, this straight-grained hardwood is used in fine furniture.

PROS: Beautiful coloration, strong, stable, versatile

CONS: Expensive, Can be difficult to finish

Cherry is a distinctive hardwood with a typically red-brown color, and fine, straight grain.

PROS: Naturally rich in color, easily shaped, polishes well

CONS: Expensive, prone to darkening in color

A premium hardwood, weather-resistant teak is commonly used for outdoor furniture. It is durable and displays a golden brown color.

PROS: Naturally durable to moisture, does not corrode iron or steel hardware, hard, strong

CONS: Expensive, when exposed to natural elements turns a silver grey if not sealed or pre-weathered

A mainstay in fine furniture, mahogany is reputed for its distinctive and attractive grain and coloration. It varies in color from medium brown to deep red-brown.

PROS: Easy to work, fairly strong

CONS: Expensive, hardness varies, prone to warping

Manufactured wood products, or composite woods, can bring the look of fine wood at an economical price point. When covered with a top-quality veneer, composite woods deliver an almost identical appearance to genuine wood, and can also have the same level of high quality.

Plywood is multiple sheets of lumber glued together under high pressure. High-quality plywood is at least 11-13 layers of wood. Plywood comes in different grades and qualities, but engineers and furniture-makers agree that high-quality plywood is proven to be just as sturdy as hardwood, and is resistant to cracking, warping, shrinking, and swelling.

Particleboard is made from compressed wood chips, sawdust, and fibers glued together. Even though particleboard is less expensive, particleboard is significantly less strong than both hardwood and plywood. Particleboard is often used in inexpensive furniture and is treated with a laminate or veneered facade.

Medium density fiberboard, or MDF, is manufactured the same way as particleboard but is made from broken down hardwood and softwood fibers instead. The fibers are compressed at high temperatures and bonded with resin, glue, or wax. MDF is very heavy, but cuts, sands, and finishes well.

Wood finishing is the process of refining or protecting a wooden surface. Wood finishes can enhance the appearance of wood, or increase its resistance to moisture and other environmental wear and damage.

Veneered wood is created by bonding a thin slice of hardwood to the surface of less expensive materials. The effect brings the look of more expensive woods at a more affordable price point. Veneers can applied in patterns to add more visual interest, but is considerably more difficult to maintain.

CONS: Veneered woods are much more susceptible to water damage than solid wood. Water exposure can cause the veneer to peel or buckle. It is hard to repair damaged veneer woods. Sanding or refinishing can reveal the lower-grade wood underneath.

Available in many different sheen levels (from high-gloss to matte), varnish is a clear, tough finish that is resistant to heat, water, alcohol, and abrasion. The clear finish can sometimes darken the wood.

Shellas is a non-toxic sealer derived from an insect resin. It is a protective coat available in many different colors, but typically adds a warm, amber color to wood. It can be affected by heat: white rings will appear underneath a hot bowl or mug.

Lacquer is a protective finish that is extremely durable and resistant to damage. Applied in many thin coats, lacquer typically describes a high-gloss finish that is often used in Asian-inspired furnishings. Lacquer can begin to discolor and yellow over time.

A stain does not protect wood, but changes the appearance of the wood. Available in a spectrum of colors, a stain is intended to darken and alter the wood color by adding pigments to its surface. When rubbed into the surface, a stain will naturally bring out the grain pattern giving the wood a more dramatic look.

Unlike other surface finishes, resins soak in and harden the individual fibers of wood. Resin-treated wood leave a natural look which makes wood almost unfinished and untreated. Resin is available in clear or colored.

Paint adds another aesthetic dimension to wood furniture and can be applied in a spectrum of colors dependent on aesthetic.

The processes of liming, pickling, and whitewashing adds an aged, weathered finish to furniture, which gives it a rustic, well lived-in appearance.

The mark of high-quality furniture is found in its craftsmanship. Wood joinery indicates the construction quality of wood furniture. You can generally find the joints and joinery by inspecting corners of furniture pieces, such as in a drawer. The following describes the most common joint types:

Butt Joint: A butt joint is the simplest joint to make, and features two surfaces attached perpendicularly by glue, fastened with nails, or screwed together. It is the weakest joint because it relies on glue, nails, or screws alone to hold the joint together.

Dowel Joint: Usually found in assemble-at-home furniture, dowel joints are connected with small wooden rods that are inserted into drilled holes and are typically reinforced with glue. The dowels offer additional holding strength even after the glue has deteriorated. Over time, dowels may shrink and become loose.

Dovetail Joint: Dovetail joints are very strong. Two surfaces are joined by wedge-shaped projections on one surface (called a tail) and is interlocked with a corresponding slot on the other surface (called a pin). Once glued, a dovetail joint does not require additional mechanical fasteners.This type of construction is often found in drawers.

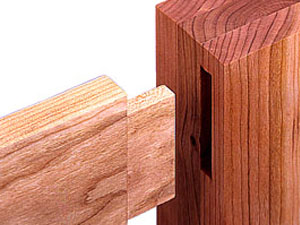

Mortise-and-Tenon Joint: Often used in cabinets and armoires, this high-quality joint connects a projecting piece (called a tenon) into the cavity (mortise) of another surface. The joint can be secured by glue, or is pinned or wedged into place. There are many variations on this basic construction type, including the additional of a peg for further support.

Prevent wood furniture from fading or cracking by keeping it out of direct sunlight and heat.

A humidifier helps maintain a healthy moisture level of 50% which is ideal for wood furniture.p

Dusting frequently is extremely important so that airborne deposits do not build up, which can can scratch the surface.

Use clean, dry, soft cloths or a feather duster to effectively remove dust.

To prevent dust build-up, lightly spray a non-toxic solution onto a cotton cloth to wipe furniture.

Never use all-purpose cleaning sprays unless furniture has a plastic coating.

To clean sticky spot, dip a soft cloth in mild soap dissolved in water, wring the cloth nearly dry, and wipe the area. Immediately dry with a clean, soft cloth.

A thin layer of wax paste will repel water and restore luster to wood furniture.

Wax wood furniture monthly. Seldom-used wood furniture can be waxed a couple times a year.

White rings on wood furniture are caused by air pockets forming when the finish begins to pull away. Work wax paste into the finish and rub briskly with a soft cloth to repair. For darker rings, customers should seek a professional to refinish the surface.